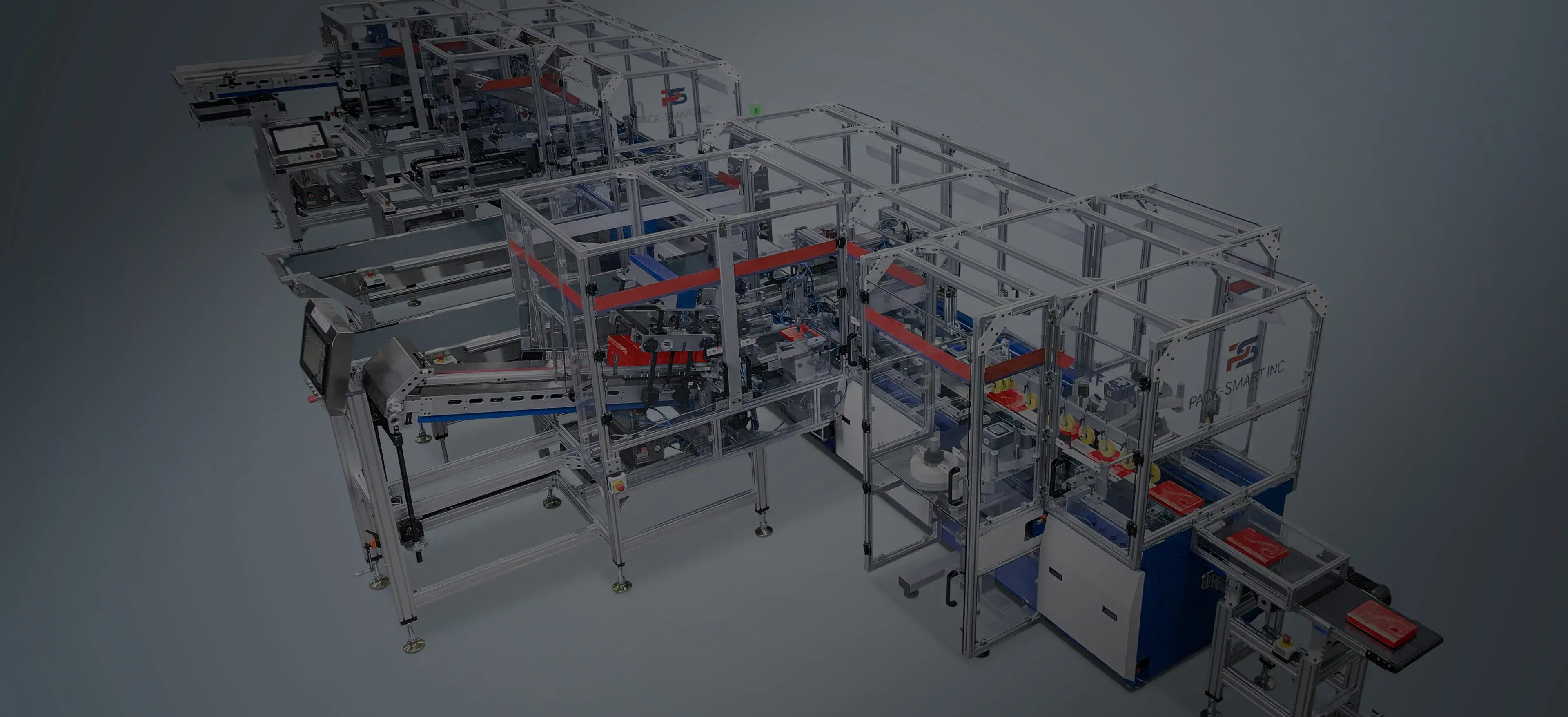

Tray Forming, Perfected — Precision at Every Step

Deliver premium-quality packaging with precision automation that boosts throughput, reduces manual labor, and enhances the consumer experience.

Precision engineering transforms packaging production

From labor-intensive bottlenecks to streamlined, high-throughput operations, Pack-Smart’s intelligent automation delivers measurable efficiency gains without compromising premium packaging standards.

up from 1,500 U/hr

down from 60+ packers

in shipping volume due to optimized flat-pack tray design

Watch the TF-3500 in Action

See precision engineering bring premium packaging to life. The TF-3500 transforms flat blanks into perfectly formed trays, combining advanced automation with the care and consistency that high-end brands demand.

Engineered for excellence

Advanced tray forming solutions crafted to deliver consistent quality, brand impact, and measurable performance gains.

Fast speeds with Precision

Process up to 3,600 trays/hour with repeatable accuracy.

Sustainability Engineered

Reduce shipping volume by 95% with innovative flat-pack tray design.

Built for Compliance

Fully Compliant with IP65 standards

Intelligent Control Platform

Real-time monitoring and full traceability with Delta-X Trust software.

Download Case Study

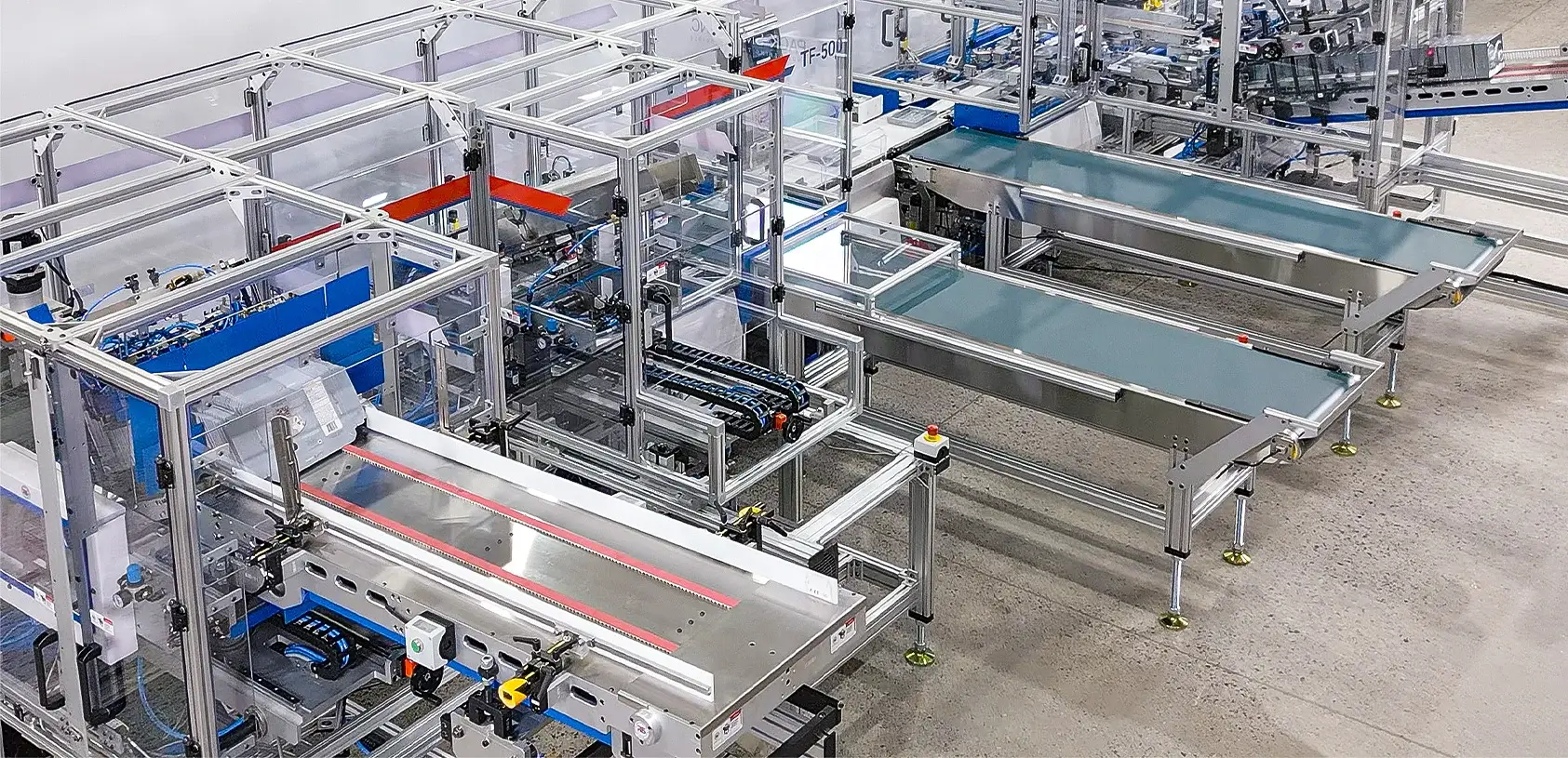

Precision Tray Forming from Blank to Box

The TF-3500 transforms blanks into high-quality trays through a seamless, engineered sequence. Each stage reflects advanced automation and meticulous design, delivering consistent precision and performance.

Base Tray Feeding

Flat-pack trays are fed into the system with precise positioning. Automated handling ensures consistent material alignment.

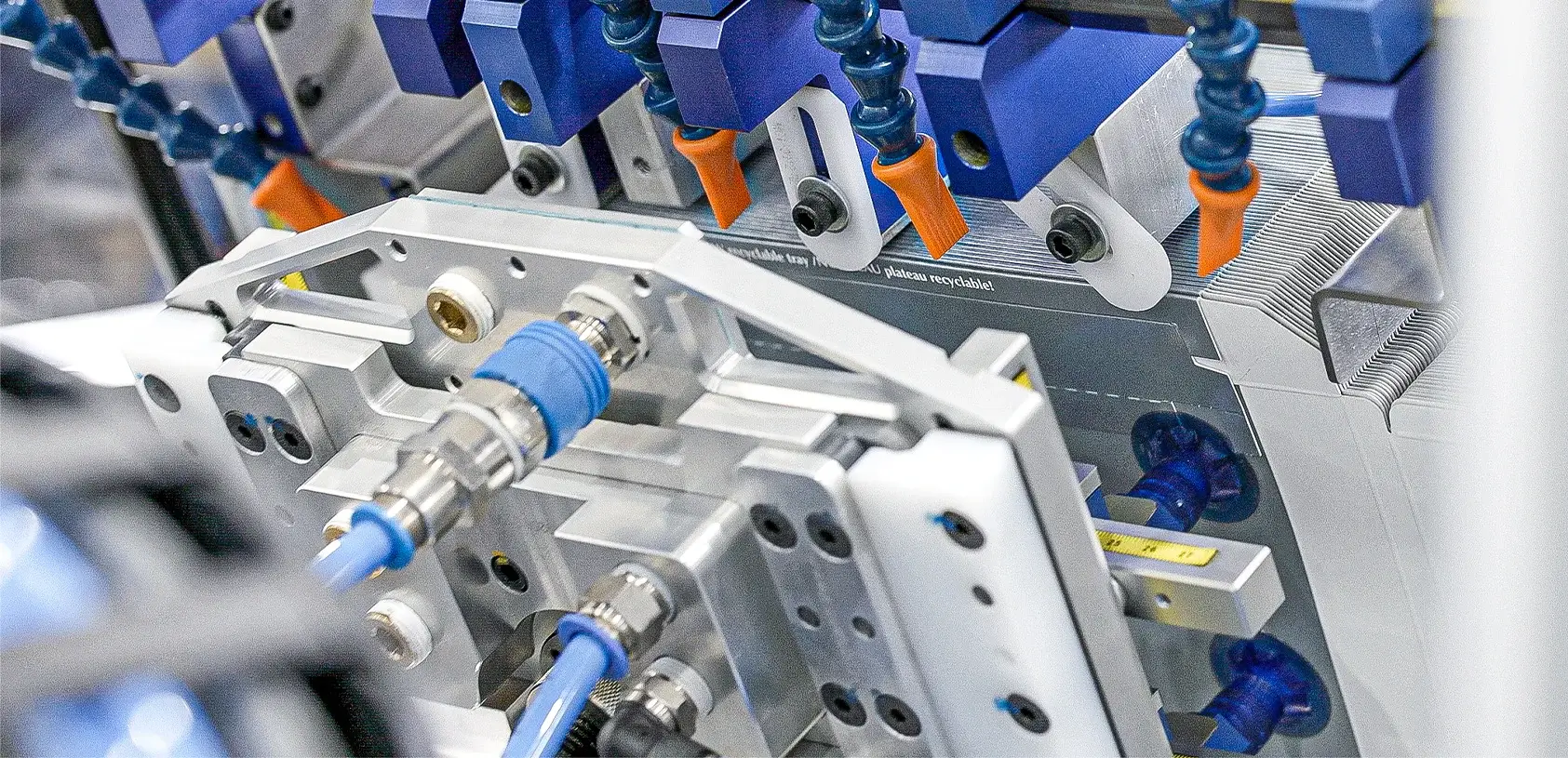

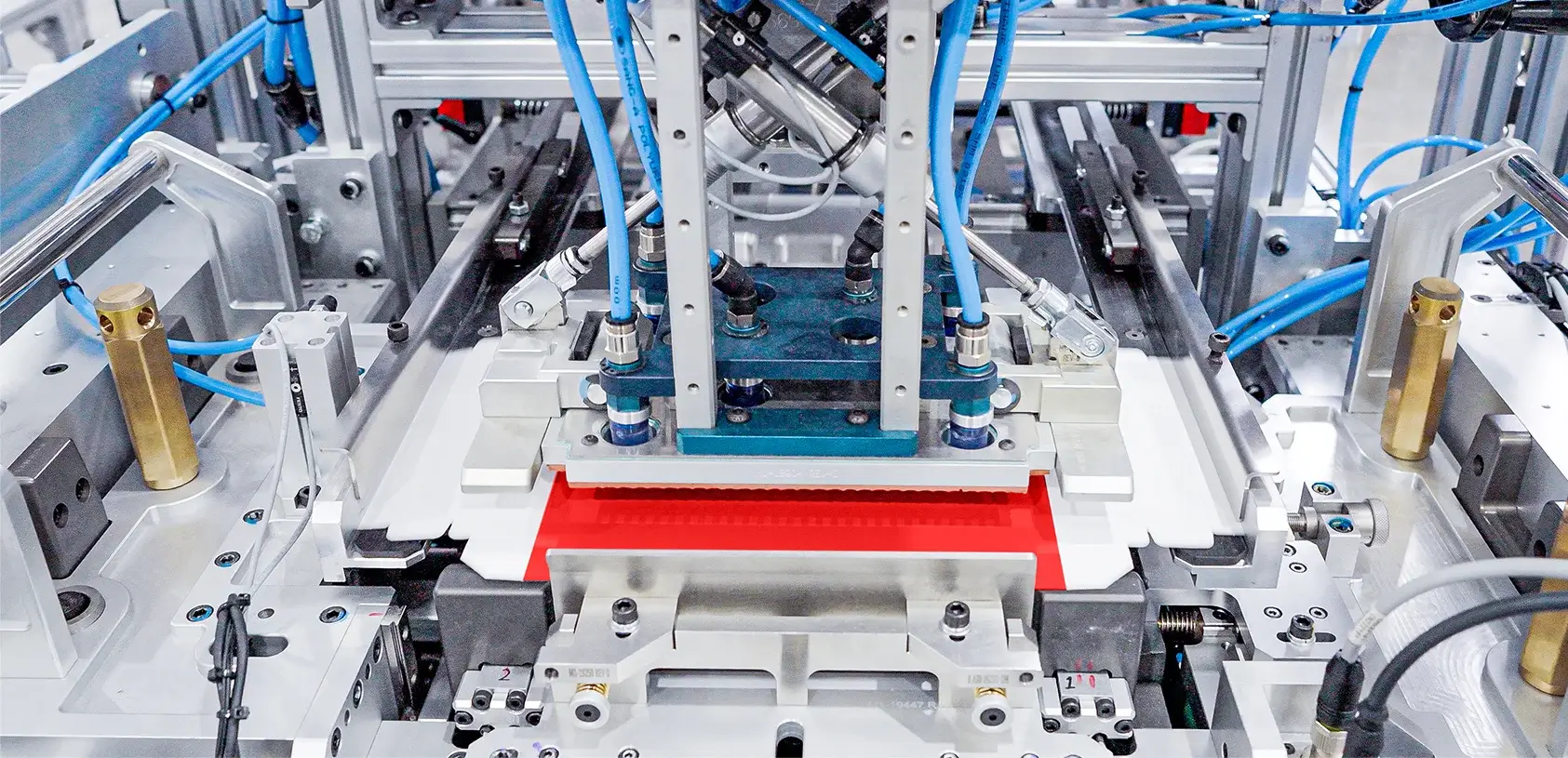

Base Tray Forming

Precision four-corner folding shapes trays with exact geometry in milliseconds. Supports sizes from 50–250 mm and board thicknesses from 10–40 pt, ensuring flexibility and consistent quality while reducing the need for pre-formed trays.

Vac Tray Placement

Vac trays are handled by a servo-driven pick-and-place system, ensuring accuracy and repeatable positioning for seamless downstream operations.

Tray Transfer for

Off-line Filling

Engineered for seamless integration with existing equipment and conveyors, the transfer module ensures smooth, accurate handoff for offline tray filling operations.

Filled Tray Weight Check & Quality Control

Each filled tray is weighed with 0.1 g precision to ensure compliance with global net quantity and food labeling standards (EU, US FDA, Codex). Non-compliant trays are automatically diverted, reducing manual handling and maintaining consistent production quality.

Tray Lid Placement

Lids are automatically positioned using a precision servo system, delivering consistent alignment and repeatable placement to maintain product quality and ensure smooth downstream processing.

Wafer Seal Application

Wafer seals are applied with precision to each package. This ensures product integrity, regulatory compliance, and provides a tamper-evident seal for enhanced consumer safety.

Finished Product Delivery

Completed trays move seamlessly to packaging or shipping. Each unit is serialized using Delta-X Tracker, ensuring traceability, audit compliance, and optimized handling for maximum operational efficiency.

Build Confidence into Every Package

The TF-3500 combines precision engineering, compliance, and real-time data to

ensure every tray meets your brand’s highest standards.

Precision engineering for safe,

sustainable packaging

Pack-Smart's TF-3500 system delivers uncompromising food safety and environmental responsibility

through innovative packaging design.

Sustainable transformation

Intelligent design reduces material waste and minimizes shipping volume.

Food safety standards met

Fully compliant with ISO 18602 and FSMA requirements for food packaging.

Environmental impact reduction

Achieve 95% shipping volume reduction with our flat-pack tray design.

Precision Packaging for

Every Application

The TF-3500 transforms blank trays into perfectly formed packaging, combining intelligent automation with engineering precision to support high-quality presentation and brand impact across industries.

Chocolate & Confectionery

Precision tray forming for delicate chocolates, minimizing material waste while enhancing brand appeal to consumers.

Bakery & Desserts

Consistent tray design that preserves product integrity, presentation, and freshness throughout distribution.

Premium Retail Packaging

Engineered solutions that enhance brand perception through high-performance, sophisticated packaging technologies.

Ready Meal Solutions

Efficient tray forming that reduces environmental impact while ensuring food safety and product protection.

Accelerate your packaging innovation

Unlock precision engineering and sustainable solutions with a personalized consultation from our packaging automation experts.

Insights

Expert knowledge to optimize your tray forming workflows and elevate packaging quality.